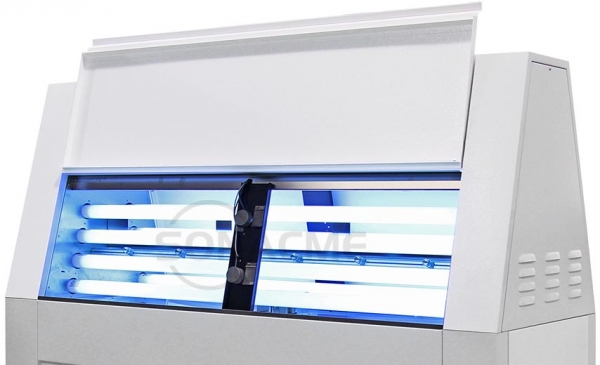

UV lamp weathering test chamber

Application area

The UV lamp weathering test chamber uses fluorescent ultraviolet lamps as the light source, and appropriately controls the temperature and humidity to periodically produce condensation on the samples to fully obtain the results of the damage of sunlight, humidity and temperature on polymer materials (material aging) Including fading, loss of gloss, strength reduction, cracking, peeling, chalking and oxidation, etc.

The fluorescent ultraviolet rays of the ultraviolet lamp can reproduce the influence of sunlight, and the condensation and water spray system can reproduce the influence of rain and dew. During the entire test cycle, the irradiation energy and temperature are controllable. A typical test cycle is usually a dark and humid condensation cycle under high temperature ultraviolet light irradiation and relative humidity at 100%; typical applications are paint coatings, automotive industry, plastic products, wood products, glue, etc.

Standard Test

AATCC TM186: Weather Resistance: UV Light and Moisture Exposure

ASTM C1257: Standard Test Method for Accelerated Weathering of Solvent-Release-Type Sealants

ASTM C1442: Practice for Conducting Tests on Sealants Using Artificial Weathering Apparatus

ASTM C1501: Standard Test Method for Color Stability of Building Construction Sealants as Determined by Laboratory Accelerated Weathering Procedures

ASTM C1519: Standard Test Method for Evaluating Durability of Building Construction Sealants by Laboratory Accelerated Weathering Procedures

ASTM C732: Standard Test Method for Aging Effects of Artificial Weathering on Latex Sealants

ISO 29664: Plastics - Artificial weathering including acidic deposition

SAE J2020: Accelerated Exposure of Automotive Exterior Materials Using a Fluorescent UV and Condensation Apparatus

Looking for a specific test standard? please contact SONACME.

Main Technical Parameters

Light source: UV-A (wavelength 340nm) or UV-B (wavelength 313nm); 40W×8 (normal service life 6000 hours)

Irradiance can be set range: 0.3 W/m2 ~ 1.55 W/m2

Blackboard temperature setting range: room temperature +10℃ ~80℃

Maximum rated power of the whole machine: 3 KW

Inner/outer shell material: all stainless steel plate 304/all stainless steel material sprayed on the surface, never rust

Exposure area: 5175cm2/828in2

Standard model: 24 standard model racks (48 150×70mm models can be put in one time

Specifications

| Model | ST/UV/A |

| Light Source | UV-A(wavelength 340nm)or UV-B(wavelength 313nm);40W×8 |

| Lamp Rated Life | Normal Service Life 6000 hours |

| Irradiance Setting Range | 0.3 W/m2 ~1.55 W/m2 |

| Maximum Rated Power | 2 KW |

| Standard Template | 24 standard sample racks (48 pieces of 150×70mm templates can be put in at one time) |

| External Dimensions of Test Chamber (L×W×H) | 1360mm×560mm×1290mm |

| Power Supply | 220V,50Hz(60Hz can be customized),Maximum current 10A |

>>> CÓ THỂ BẠN QUAN TÂM >>>

Tủ thử nghiệm lão hóa do thời tiết

Tủ thử nghiệm nhiệt độ, áp suất theo độ cao

Tủ thử nghiệm chống xâm nhập IPx

Thiết bị thử nghiệm rơi và va đập

SONACME Technology (Guangdong) Co.,Ltd. Established At 1995 With Europe Technologies, With Abundant Capital Invested At 2016 To Become A Backup Listed Company, We Re-Registered Our Company To Be SONACME Technology (Guangdong) Co.,Ltd. With More Than Two Decades Hard Working In This Industry, We Built Our Own Manufacture Facility At 2006, Capacity Reaches To 12,000 Square Meters Which Allow Us To Provide Customers With One-Stop Station Products And Services From R & D, Sheet Metal Processing, Mass Production, Sales Service, After-Sales Service, Rent & Lease,Internal Testing To Import & Export.

We Dedicate To Provide Technologies And Whole Solutions With Most Secure And Reliable Environmental Test Chambers For Our Client. Achieved 'National High-Tech Enterprise' Award And Became An CASC Permanent Member. Certified By ZRX With ISO9001:2015 And ISO14001:2015 And Recently Verified By Alibaba With Gold Plus Supplier.

Tiếng Việt

Tiếng Việt English

English