Pressure Testing H2 Components

Our flagship H2 test bench is utilised in research & development. In addition, it is used for constant benchmarking of the manufacturing process to validate H2 component quality. The rig is qualified to test H2 components such as 0n-tank valves, sensors, hoses, fuel cell components and more.

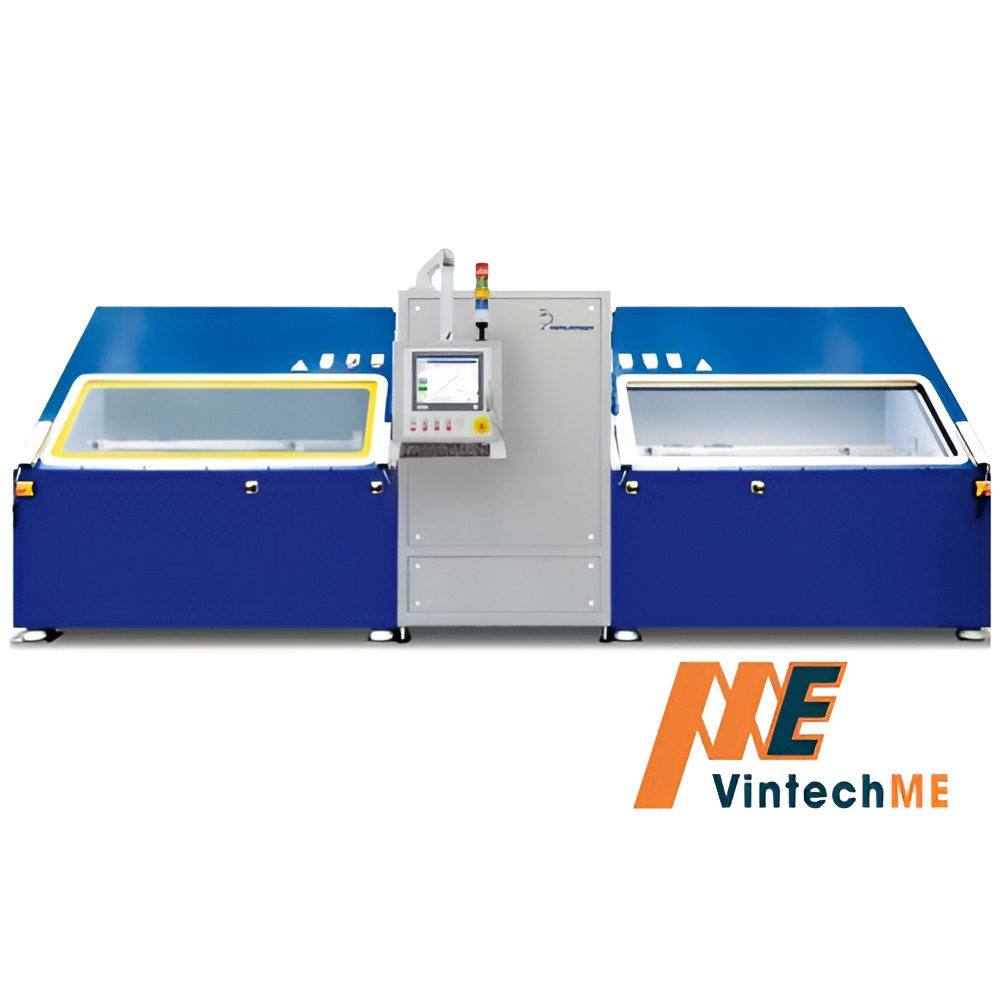

R&D Pressure Pulsation Test Stand for H2 Components up to 2000 bar

P+P test stands are used in research & development and to constantly benchmark the manufacturing process and H2 component quality. To guarantee the safety of media-carrying components during their entire service life, components must undergo endurance tests under extreme load and temperature changes. P+P offers and uses flexible solutions while simulating diverse conditions and environments. Our test systems allow for leak tests with a range of more than 1050 bars, depending on the specification.

The test stand can be expanded with several expansion stages. Depending on the option selected, pressure cycle tests up to 2,000 bar and 10 Hz can be generated in addition to the gas test. Pressure ramps of up to 3,000 bar can be generated with the test circuit for hydrostatic and burst pressure tests.

The system consists of two modules. The tests can be carried out in a climate chamber, in which the components can be exposed to media and outside temperatures from -40 °F (-40 °C) to +320 °F (+160 °C). The individual printing units are precisely tailored to the properties and components of the customer in order to generate ideal test conditions. A common setup in the industry and for this specific test stand is one intensifier for 1000 psi (70 bar), two for up to 4000 psi (275 bar) and one for up to 6000 psi (414 bar). A typical test medium is water, glycol, aerospace oil, gas, and other oils.

Performance Data

+For pressure tests according to EG79 / EU406 – Section 4.2 and ECE R134

+Pressure booster for additional supply

+Displacement volume max. 15cm³

+Frequency up to 10Hz

+Pressure Load Changes as sine & trapezoidal curve (depending on the expansion volume)

+Impulse intensifier for small volumes up to 2,000bar

+Safety test chamber with automatic door

+Media treatment with dirt and a clean tank

+Refill for pressure change test complete electrotechnical equipment for pressure tests

+Controller for maximum precision

+Hydraulic power pack with Moog RKP and 55kW

+Preparation for connection for second test chamber

+Test medium hydraulic oil

+Displacement volume max. 600 cm.

+Frequency up to 10Hz

+Pressure curve programable as sine & square (trapezoidal) curve

+Including the extension of the hydraulic unit to 75 kW

+1050 bar gas/helium /nitrogen/hydrogen

Fields of application:

+Hydrogen (H2) components

+Pressure tests according to EG79 /

+EU406 and R134

Technical specifications:

+Test media: Oil (HLP 46)

+A total of 3 test tracks for pressure cyle tests

+Max. 2.000 bar for 15 cm³

+Max. 1.500 bar for 500 cm³

+Max. 50 bar for 1.000 cm³

+Pressure intensifier for bursting up to 3.200 bar (200 cm³)

+Reloading of the pressure intensifieres

+Frequency up to 10 Hz (depents on test setup)

+Safety chamber with automatic door

+Climate chamber for regulated ambient temperature from -40 °C up to +160 °C

+Media filtration unit with clean and dirt tank-system

+High precision controller integrated

Tham khảo thêm các sản phẩm tại:

Automotive - Poppe+Potthoff Maschinenbau (poppe-potthoff-maschinenbau.com)

>>> CÓ THỂ BẠN QUAN TÂM >>>

Tủ thử nghiệm lão hóa do thời tiết

Tủ thử nghiệm nhiệt độ, áp suất theo độ cao

Tủ thử nghiệm chống xâm nhập IPx

Thiết bị thử nghiệm rơi và va đập

Company Poppe + Potthoff Maschinenbau headquartered in Nordhausen, Thuringia employs a team of around 50 people. We have many years of experience in testing and high-pressure technology as well as in special machine building. The focus is on testing components made of various materials in different pressure ranges up to 16,000 bar. Among the offered tests as a service and custom pressure test rigs are vacuum test applications, autofrettage, pressure cycle, burst testing, leak testing and automation solutions for various industries such as the automotive and supplier industry. As a specialist in high-pressure technology, Poppe + Potthoff Maschinenbau supports the development and production of extremely resilient components.

Poppe + Potthoff Maschinenbau is a proud part of the Poppe + Potthoff Group and was founded in 2007 to support research and development as well as the production of a variety of different components within the group. This has grown into a market-leading company in the development of pressure test benches. Poppe + Potthoff Maschinenbau supports hundreds of companies and global players worldwide with state-of-the-art test benches.

The Poppe + Potthoff Group

Founded as a tube manufacturer in 1928, the P+P Group now employs 1,600 people worldwide and, based on its expertise in a wide range of metal processing, serves a wide variety of customers in over 50 countries with creative solutions. From the traditional strengths in the field of precision steel tubes, common rails and lines for diesel injection systems, testing machines, as well as precision components and couplings, we have developed new technologies and systems for hydrogen for an emission-free future. With targeted investments in young companies, we create an ecosystem with which we support our customers in the challenges of sustainability as well as those of digitization.

Tiếng Việt

Tiếng Việt English

English