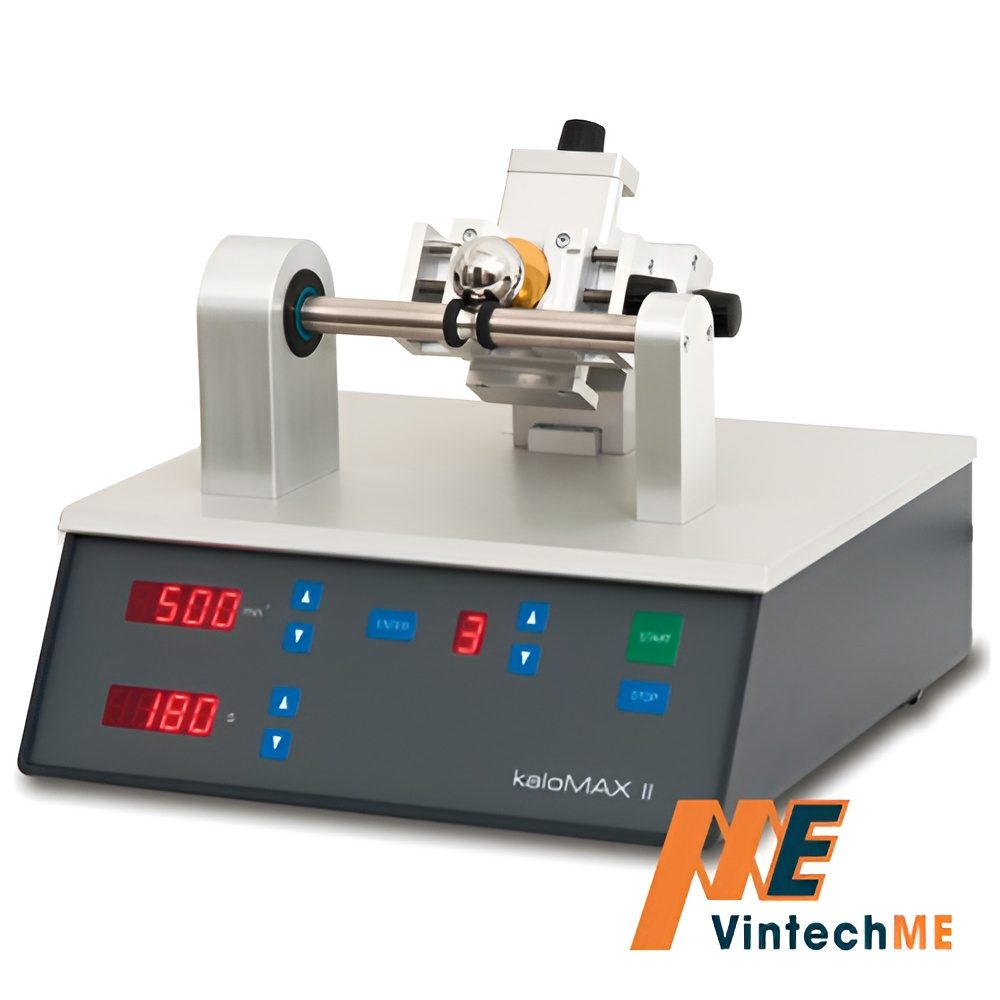

Spherical cap grinder (Calotest device) for the determination of layer thicknesses

- Fast and easy layer thickness measurement

- Measurement of single layer and layer systems

- Measurement independent of the material

- Comfortable operation

- Precise measurement without calibration

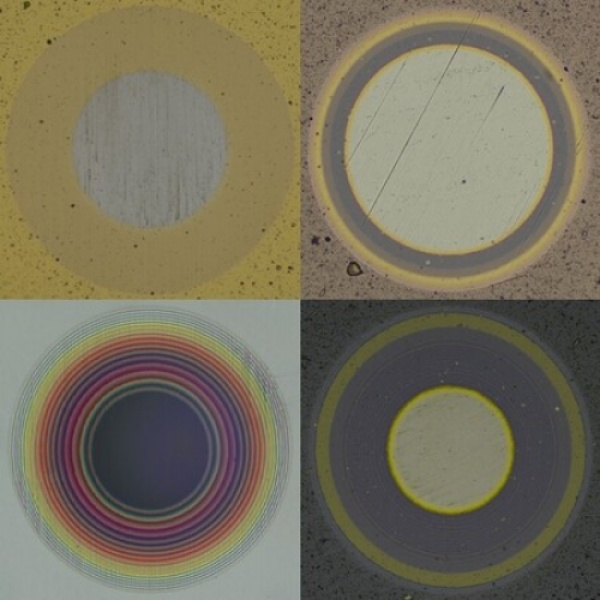

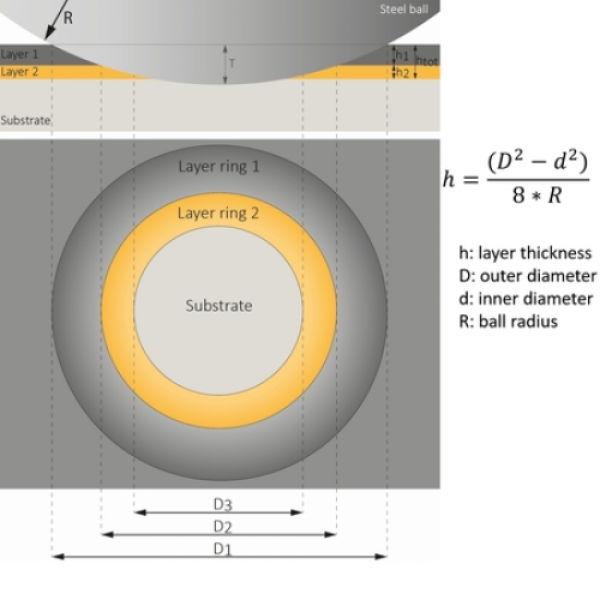

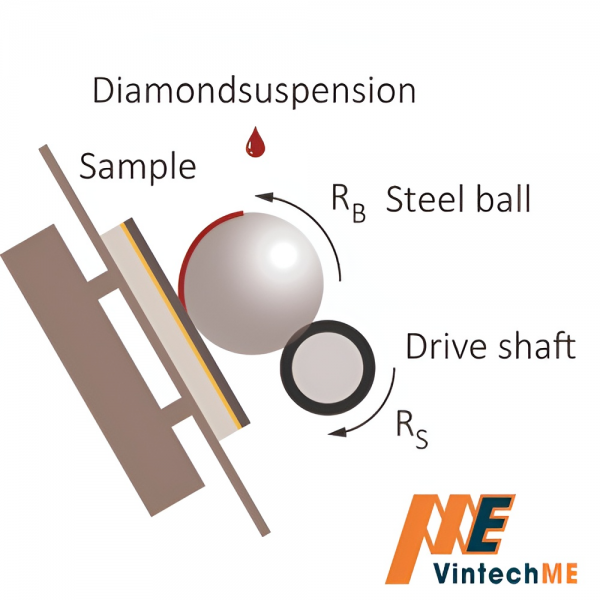

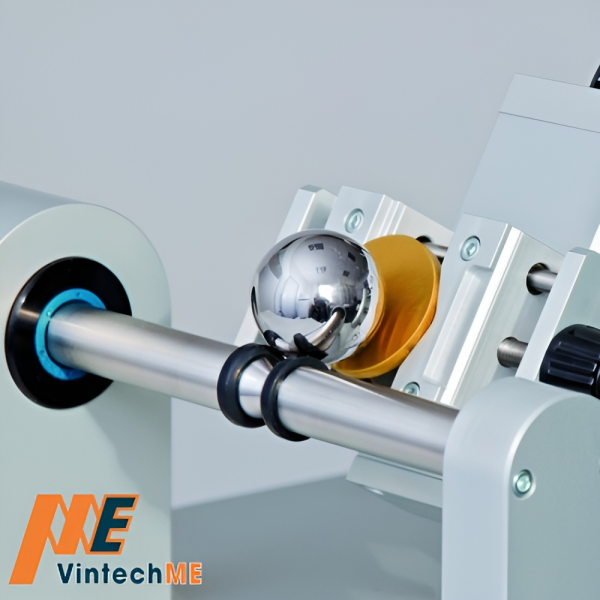

The ball crater test (Calotest) is a well established method for the determination of layer thickness. With a rotating steel ball and an abrasive slurry, a spherical cap is ground through the coating into the base material of the sample. When examined with a microscope, the layer/base material interface appears as a circle or, in case of a multilayer coating, a system of concentric circles. The layer thickness can be calculated from the diameters of these circles and the diameter of the grinding ball.

This purely geometrical method gives highly accurate results even for layer thicknesses in the range of micrometers.

Evaluation and documentation can be further simplified by the software kaloSOFT and a camera-equipped microscope.

Technical Data

|

Layer thicknesses |

Approx. 0.3 – 30 μm |

|

Diameter of the spherical cap |

Approx. 0.1 – 2 mm |

|

Measurement accuracy |

1 – 5 % (dependent on surface roughness) |

|

Characteristics: |

|

|

Ball diameter |

15 – 30 mm |

|

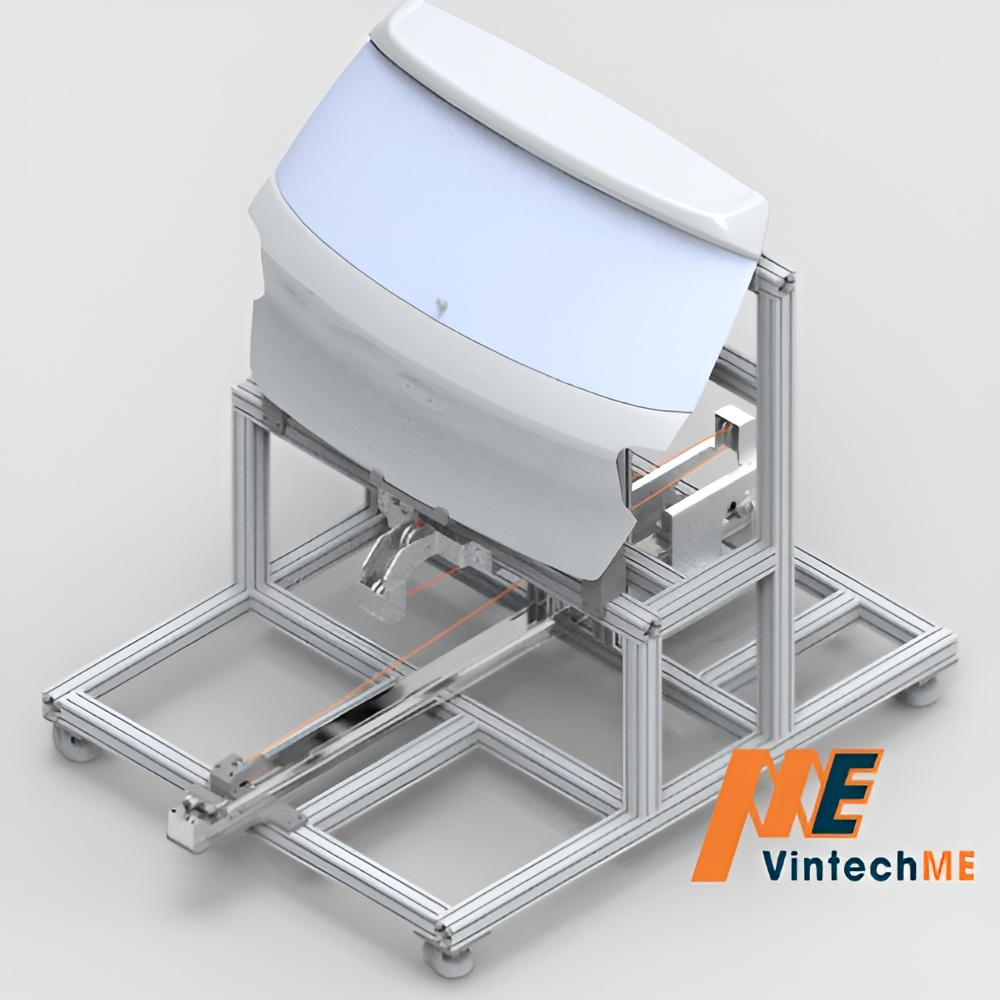

Clamping range for plane samples |

50 mm |

|

Clamping range for round samples |

3 – 30 mm (clamping jaw for other dimensions on request) |

|

Cross table travel |

25 x 25 mm |

|

Incline of sample level |

60 degrees |

|

LED displays (14 mm height) |

4 digits number of revolutions |

|

4 digits runtime |

|

|

1 digit program number |

|

|

Number or revolutions of the drive shaft |

100, 200, 300, 400, 500, 600, 700, 800, 900, 1000, 1100, 1200 1/min |

|

Running periods |

5, 10, 15, 20, 25, 30, 35, 40, 45, 50, 55, 60, 70, 80, 90, 100, 110, 120, 150, 180 s |

|

Input voltage range |

85 – 264 VAC |

|

Input frequency range |

47 – 63 Hz |

|

Dimensions |

300 x 295 x 235 mm (w / d / h) |

|

Weight |

Approx. 8 kg |

>>> CÓ THỂ BẠN QUAN TÂM >>>

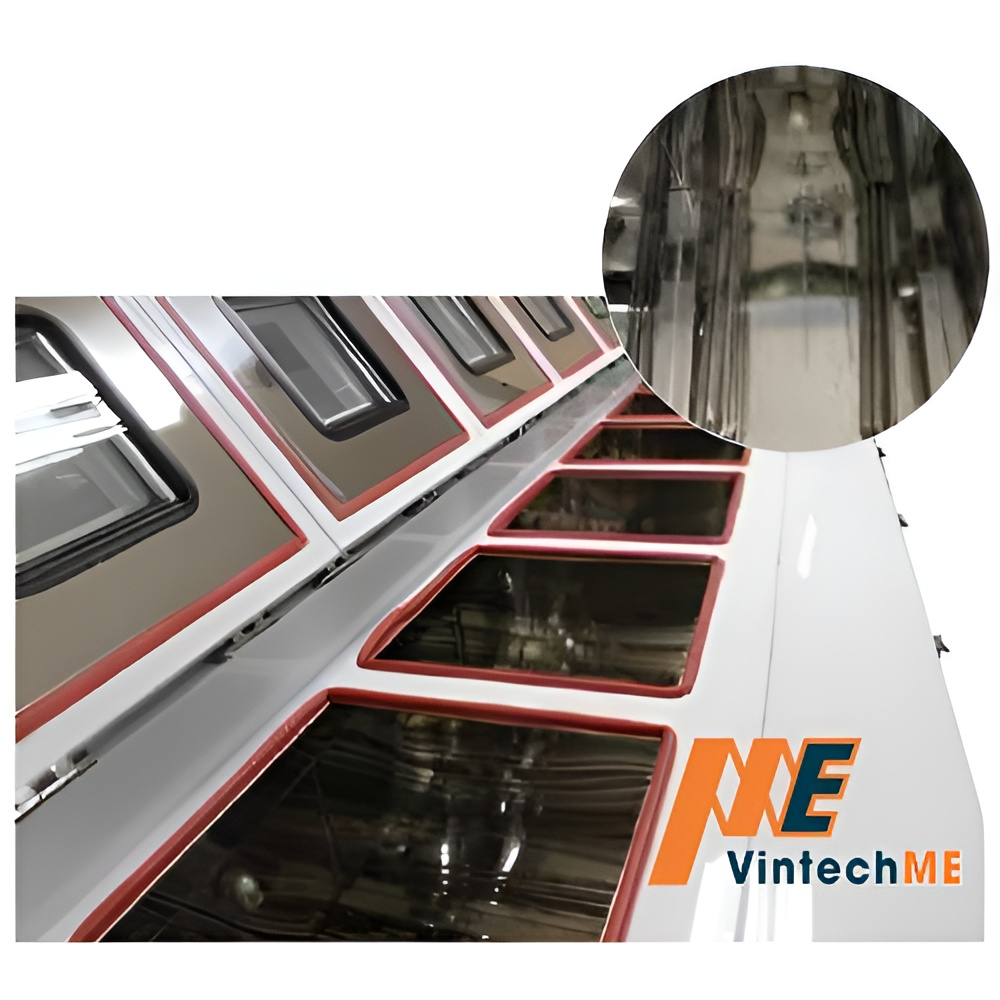

Tủ thử nghiệm lão hóa do thời tiết

Tủ thử nghiệm nhiệt độ, áp suất theo độ cao

Tủ thử nghiệm chống xâm nhập IPx

Thiết bị thử nghiệm rơi và va đập

BAQ GmbH is operating in the field of material testing since 1992. The product range covers stationary and portable hardness testers (Vickers, Rockwell, Brinell, Shore, impact hardness and ultrasonic contact impedance (UCI) method) as well as devices for testing layer thickness, abrasion resistance, scratching resistance and coating adhesion strength. These devices are used in all areas of material testing, e.g. inspection of incoming goods, production, research and development. More than 25 years of experience and continuous cooperation with the Fraunhofer Institute for Surface Engineering and Thin Films and others as well as in-house development and production in Germany guarantee good quality and optimal service. BAQ also offers optimized solutions for special requirements.

.png)

Tiếng Việt

Tiếng Việt English

English