VOC emission test chamber can provide standard testing environment such as temperature humidity, air exchange rate and airflow to simulate real indoor environment to test the pollutant release rate and release properties of various indoor materials and products.

Features

1. Controls environmental conditions(Temperature, Relative Humidity, Air changes per hour and air velocity) inside the test chamber 1m³, 3m³ or other volumes optionally available

2. Prevention of contamination from the surrounding environment

3. Minimal adsorption effects

Applicable Standard

It is mainly used to detect the amount of formaldehyde and VOC released from interior decoration materials, decoration and decoration materials, wood-based panels, wood products, and other products. According to indoor pollutant data or prediction model, the indoor air is evaluated by comprehensive environmental indicators.

ISO 16000-9-2006 (Determination of Volatile Organic Compounds Released from Building Products and Furniture-Laboratory Release Method)

ASTM D5116-97 (Standard Guide for the determination of organic releases from indoor materials and products in small scale environmental chambers)

ASTM D6330-98 (Specifies the standard operation for the determination of VOC release from wooden panels in a small environmental chamber under test conditions)

ASTM D6670-01 (Standard procedure for measuring VOC releases from indoor materials and products in full-scale environmental chambers)

ENV 13419-1 (Determination of VOC emissions from building products Part 1 method for releasing a test environment chamber)

GB 18580-2017(Formaldehyde emission limits in wood-based panels and self products for interior decoration)

GB 18584-2011(Interior Decoration and Decoration Material - Limit of Hazardous Substances in Wood

Furniture) (in approval)

GB 18587-2001 (Indoor Decoration Materials - Carpets, Carpet Liners and Carpet Adhesives Harmful Substances Release Limits)Appendix A (Normative Appendix): Small Environmental Test Chamber Method.

GB 50325-2010 (Control specification for Indoor Environmental Pollution Control in Civil Building Engineering)

GB/T 18584 General Technical Conditions for Climate Chamber for Detection of Volatile Organic

Compounds in Furniture (Draft for Approval)

GB/T 28489-2012 (Harmful Material Limit for Musical Instruments)

GB/T29592-2013 GB/T 29592-2013 (Determination of Volatile Organic Compounds (VOC) and Aldehydes in Building Adhesives)

LY/T 1980-2011 (Volatile Organic Compounds and Formaldehyde Emission Detection chamber)

LY/T 1981-2011 (Detection chamber for formaldehyde emission gas analysis)

JG/T 344-2011 (Building Engineering Indoor Environment Test Chamber)

HJ 571-2010 (Technical Requirements for Environmental Marking Products Wood-based Panels and self Products)

HJ/T 201-2005 (Technical Requirements for Environmental Marking Products Waterborne coatings)

HJ/T 220-2005 (Technical Requirements for Environmental Marking Products adhesive)

HJ/T 414-2007 (Technical Requirements for Environmental Marking Products Solvent-based Wood Coatings for Interior Decoration)

Specification

|

1 |

Volume size |

Workroom volume |

1000L±20L |

|

|

|

Workroom |

850×1100×1080mm(Wide, Deep, High) |

|

|

|

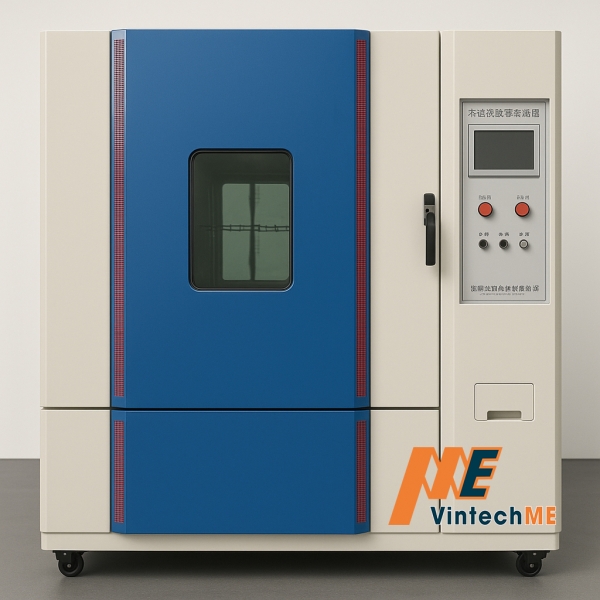

Appearance |

Subject to reality |

|

|

|

Gate (door) |

850×1080mm(Wide, High) |

|

|

|

Observation window |

370×540mm(Wide, High) |

|

2 |

Temperature |

Temperature range |

15~45 ℃ |

|

|

|

Temperature fluctuation |

<±0.3 ℃ |

|

|

|

Temperature deviation |

<±0.5℃ |

|

3 |

Humidity |

Humidity range |

20~85% RH |

|

|

|

Humidity fluctuation |

≤ ± 2% RH |

|

|

|

Humidity deviation |

≤ ±2.5% RH |

|

4 |

Backgroundvalue |

Formaldehyde background value |

≤0.006 mg/m3 |

|

|

|

Single VOC background |

≤0.002 mg/m3 |

|

|

|

TVOC background value |

≤0.02 mg/m3 |

|

5 |

Ventilation and sealing |

Air exchange rate |

0.2~2.5 times/h |

|

|

|

Center wind speed (adjustable) |

0.1~1.0 m/s |

|

|

|

Tightness |

a) When the positive pressure (gauge pressure) is 1kPa, the air leakage rate in the cabin is VL < 0.5% × cabin capacity/min; b) The air leakage rate in the cabin is VL<5%×air supply rate Vs. |

|

|

|

Recovery rate |

>80 % |

|

|

|

Relative barotropic pressure maintained |

10±5 Pa |

|

6 |

Material |

Cabin material |

SUS304 mirror stainless steel 1.5mm, round corner, full welding and polishing |

|

|

|

Shell material |

Q235A cold rolled steel plate 1.5mm, surface electrostatic spraying, white |

|

|

|

Sealing material |

Imported PTFE and fluororubber |

|

|

|

The insulation material |

100 mm,High Density Polyurethane Foaming |

|

7 |

Operation and monitoring |

Interface |

Delta 7 inch color touch screen (with Ethernet port, remote control) |

|

|

|

Device control mode |

The following control modes can be realized: ①Local Control: Operate the device directly on the touch screen ②Area control: View and control equipment on any LAN computer

③Distant Control: Access Control Devices can be accessed anywhere via the Internet |

|

8 |

Safety protection |

System protection |

①Cabin high temperature protection ②Overload, Leakage, Phase Shortage, Undervoltage, Overvoltage and Phase Sequence Protection of Power Supply ③High and low pressure protection of refrigeration system,overload protection ④Overheat Protection of Heating Components ⑤Anti load impact Design ⑥Motor overcurrent protection ⑦Draught fans Overheat and Overload Protection of Air Pump ⑧Humidification and water shortage protection ⑨Pressure protection |

|

9 |

Interface |

Data interface |

The device provides the following external interfaces: ①USB A:1 ②USB B:1 ③RJ-45:1 ④RS232:1 |

|

10 |

Other |

Sampling interface |

3 (Φ8mm) |

|

|

|

Noise |

≤60dB |

|

|

|

Cover an area of |

1.7×2.8 m(Wide by deep, with open door and surrounding heat dissipation space) |

|

|

|

Power supply |

AC380V 6KW |

|

|

|

Humidifying water |

Distilled water |

|

|

|

Water replenishing cycle |

>20 days (continuous operation) |

.png)

Tiếng Việt

Tiếng Việt English

English