Horizontal Flammability Testing Equipment

Horizontal Flammability Tester, to determine the flammability of textiles and automotive interior. Complies with ISO 3795, ASTM D5132, FMVSS 302, etc.

Horizontal Flammability Tester, to determine the flammability of textiles and automotive interior. Complies with ISO 3795, ASTM D5132, FMVSS 302, etc.

This machine is suitable for abrasion resistance test of various plastic products such as computers, mobile phones (P.D.A), MP3, CD/VCD/DVD, cordless phones, electronic dictionaries, etc.

This machine is suitable for life testing of buttons of small consumer electronic products such as mobile phones, telephones, car devices, PDAs, Bluetooth/hands-free headsets, TV remote controls/computer controllers, MP3/CDs, etc.

Top model film thickness meter with built-in printer Electromagnetic and eddy current probes sold separately (required options) Block/group statistical calculation function

Suitable for ferrous metal, non-ferrous metals, IC thin sections, coatings, ply-metals; glass, ceramics, agate, precious stones, thin plastic sections etc.; hardness testing such as that on the depth and the trapezium of the carbonized layers and quench hardened layers

Electromagnetic film thickness meter LE-373 use measuring the thickness of non-magnetic coating on magnetic material

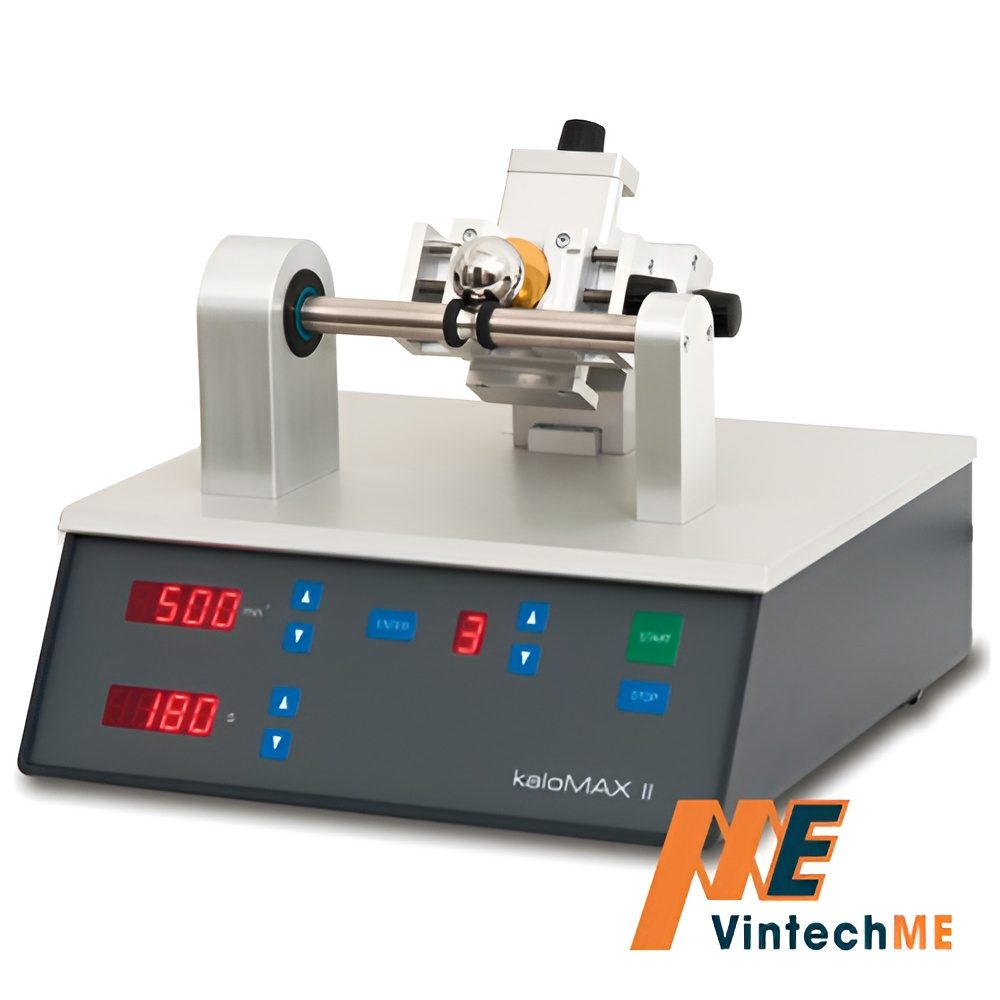

The ball crater test (Calotest) is a well established method for the determination of layer thickness. With a rotating steel ball and an abrasive slurry, a spherical cap is ground through the coating into the base material of the sample. When examined with a microscope, the layer/base material interface appears as a circle or, in case of a multilayer coating, a system of concentric circles. The layer thickness can be calculated from the diameters of these circles and the diameter of the grinding ball.

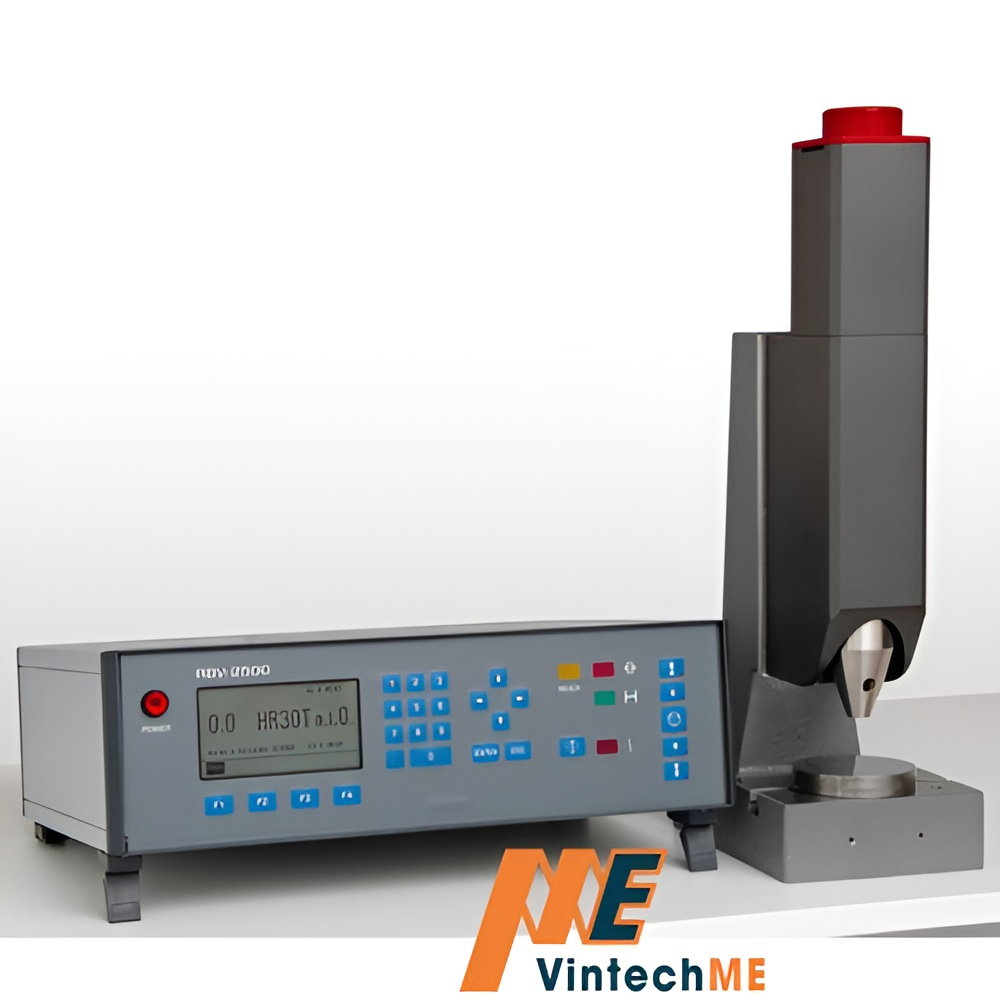

The hardness testing machines are designed for production support and 100%-Checks for higher quantities. Owing to the new design you are able to integrate it into production plants without any problems.

The UT200 is a universally usable, fully automated Hardness tester. The Die computer-controlled positioning offers the possibility for hardness testing on lines and surfaces as well as the fast and automated testing of numerous pieces in the production or the receiving area.

Incoming goods inspection. Hardness testing of metals in production. Testing of machine parts, weld seams, coatings and hardened parts even at difficult to access locations and at any angle

Incoming goods inspection.Hardness testing of metals in production. Testing of machine parts, weld seams, coatings and hardened parts even at difficult to access locations and at any angle.

The King Portable Tester is a mobile tester that is suitable for use in the lab or in the plant. It is easy to operate and convenient to carry. It can be used to test all sizes of parts and parts in any direction (like upside down, underside, or side face). When the part cannot be moved easily, the King Tester is the answer. The King Tester applies the same principle as a bench type Brinell hardness tester.