Over View

Liquid-cooled high and low temperature test chamber is a device used to test the performance of materials or products under extreme temperatures. It can simulate drastic changes in ambient temperature and usually achieve rapid transitions between high and low temperatures to facilitate the evaluatio

Advantages of Sanwood Test chamber

The liquid-cooled high and low temperature integrated test chamber can simulate drastic changes in ambient temperature and usually achieve rapid transitions between high and low temperatures to facilitate the evaluation of the reliability and stability of materials or products under these conditions.

- Rapid heating and cooling: The efficient refrigeration and heating system design can achieve rapid heating and cooling, shortening the test time.

- The equipment manufacturing complies with UN38.3 , UL, IEC, SAE, GB/T testing standards.

- Multiple test modes: It can perform multiple experimental modes such as constant temperature, cycle, alternating temperature, etc., suitable for different test needs.

- Can cooperate with unmanned automation design to save labor costs.

- Designed and manufactured in accordance with international standards, with high reliability and stability.

The battery explosion-proof test chamber is widely used in the battery manufacturing industry, new energy vehicle industry and related R&D laboratories.

Application Fields of Liquid-cooled Test Chamber

Liquid-cooled high and low temperature integrated test chamber is a multi-functional climate test equipment, widely used in scientific research, industry and quality inspection and other fields.Common applications are as follows:

- Electronic and electrical: Test the performance and reliability of electronic components in high and low temperature environments.

- Material science: Evaluate the changes in physical and chemical properties of various materials under extreme temperatures.

- Automotive industry: Used to test the weather resistance and stability of automotive parts.

- Aerospace: Simulate the working conditions of spacecraft at extreme temperatures.

The liquid-cooled high and low temperature integrated test chamber adopts liquid cooling technology to quickly reduce the temperature through flowing liquid coolant. Compared with the traditional air cooling system, the liquid cooling method can reach the set temperature faster and maintain a stable temperature environment.

The Test Standards Of Liquid-cooled test Chamber

The test standards of liquid-cooled high and low temperature test chambers usually depend on the specific application field and product type of the test. The following are some common test standards and specifications that are applicable to some scenarios of high and low temperature testing:

- ISO 16750: A test standard for automotive electronics that includes testing under temperature and humidity conditions.

- MIL-STD-810: A U.S. military standard that provides test methods for equipment under extreme temperature conditions. Applicable to equipment in the military and aerospace fields.

- IEC 60068-2-2: Environmental testing - Part 1: Test B: High temperature test. Again, this is an IEC standard that provides specifications for high temperature testing.

- IEC 60068-2-1: Environmental testing - Part 1: Test A: Low temperature test. This is an International Electrotechnical Commission (IEC) standard that specifies the procedures for testing under low temperature conditions.

The above standards and test methods can be adjusted and selected according to actual needs to better meet specific test requirements.

Control System Of Liquid-cooled Test Chambers

The controller system of Sanwood test chamber adopts world leading hardware and software systems to ensure that the test box operates under preset conditions, providing accurate and reliable experimental data to help users achieve precise control and data collection of various experimental conditions.

- Controller: The TEMI 1500 controller imported from Sanwontech in South Korea and the self-developed Siemens control system are used, equipped with RS232, RS485, and Ethernet communication ports.

- Programmable control: supports setting experimental programs, such as heating, cooling, holding time, etc., and executing multiple program settings.Support advance reservation for power on function.

- Multiple languages optional: English, Korean, Russian, Chinese, and Japanese.

- Remote monitoring: Using SAMWON-EZNET network remote technology to achieve remote control, the test chamber can be monitored at any time and emails can be sent to users' PCs and phones, enhancing convenience.

The specific control system of the test chamber may vary depending on the model, so it is necessary to carefully read the Sanwood Environmental Test Chamber Manual and follow safety operating procedures before use.

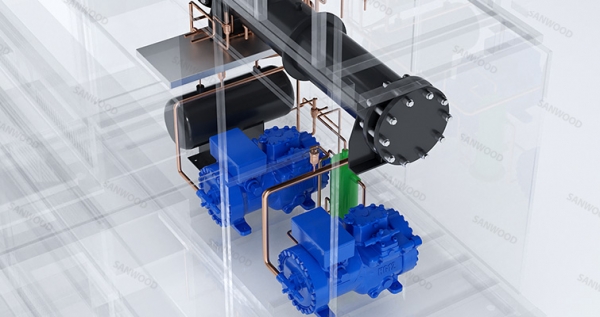

Refrigeration System Of Liquid-cooled Test Chamber

The refrigeration system of the test chamber is a complex and important system, and the quality of the refrigeration system is crucial for the accuracy and reliability of the test results.

- Sanwood has developed hot air refrigerant defrosting technology, which effectively melts the frost on the evaporator by injecting high-temperature and high-pressure refrigerant vapor into the heat exchanger inside the test chamber. This not only ensures that the evaporator does not frost, but also greatly reduces the energy consumption of the equipment.

- The refrigeration unit adopts international famous brands and cooperates with Japan's Eginomiya and the US Sporan to develop EPV series and XUP series quick opening solenoid valves for energy-saving systems, with an all-weather service life of over 15 years. And began to develop the new Danfoss AKV series throttling electronic expansion valve system, which is more efficient and energy-saving.

- Optimizing the layout of the refrigeration system adopts VRF (refrigerant flow control) technology based on PID cold end output principle to achieve low-temperature energy-saving operation, which can reduce energy consumption by 30% under low-temperature conditions.

- The refrigeration system adopts modular design, achieving low failure rate,less welding joints, high refrigeration efficiency, good reliability, simple maintenance, and low repair costs.

Technical data sheet

|

Model |

SMC-80-CC-FB |

SMC-150-CC-FB |

SMC-225-CC-FB |

SMC-408-CC-FB |

SMC-800-CC-FB |

SMC-1000-CC-FB |

SMC-1500-CC-FB |

|

Internal (mm) |

500*500*400 |

500*600*500 |

500*750*600 |

800*850*600 |

1000*1000*800 |

1000*1000*1000 |

1200*1000*1250 |

|

Outer Size (mm) |

700*1680*1180 |

700*1720*1275 |

700*1930*1290 |

1000*2050*1400 |

1200*2100*1590 |

1200*2100*1780 |

1400*2100*2030 |

|

Volume (L) |

80 |

150 |

225 |

408 |

800 |

1000 |

1500 |

|

Weight (kg) |

280 |

380 |

450 |

620 |

690 |

840 |

955 |

|

Temperature Control Range |

-70°C ~ +180°C (A: 0°C ~ +180°C; B: -20°C ~ +180°C; C: -40°C ~ +180°C; D: -70°C ~ +180°C) |

||||||

|

Temperature Fluctuation |

±0.5°C |

||||||

|

Cooling Rate |

180.0°C ~ 25.0°C for about 100 minutes, 2.0~3.0°C/min |

||||||

|

Heating Rate |

-70.0°C ~ +180.0°C for about 60 minutes, 3.0~5.0°C/min |

||||||

|

Temperature Uniformity |

≤1.5°C (-40.0°C ~ +100.0°C) |

||||||

|

Humidity Control Range |

20.0% RH to 98.0% RH (corresponding to 20% RH above 60°C) |

||||||

|

Humidity Fluctuation |

±1.0% RH |

||||||

|

Humidity Uniformity |

±2.0% RH |

||||||

Sanwood Environmental Testing Chamber Co.,Ltd established at 1995 with Taiwan technologies, with abundant capital invested at 2013 to become a backup listed company, we re-registered our company to be Guangdong Sanwood Technology Co.,Ltd. With more than two decades hard working in this industry, we built our own manufacture facility at 2017, capacity reaches to 12,000 square meters which allow us to provide customers with one-stop station products and services from R & D, Sheet metal processing, mass production, sales service, after-sales service, rent & lease, internal testing to import & export.

We dedicate to provide technologies and whole solutions with most secure and reliable environmental test chambers for our client.Achieved ‘National High-tech Enterprise’ award and became an CASC permanent member. Certified by ZRX with ISO9001:2015 and ISO14001:2015 and recently verified by Alibaba with Gold Plus supplier.

Our valued clients included but not limited to: Science & Research, Military Industry, National Defense, Universities & Colleges, Quality Inspection, Automotive, New Energy, Batteries, opto-electronic, AI, Precision electronics, electrical tools,medical,telecommunications. With clients points of view and demands-orientation, we consider every details in our product research & development and after-sales service to pursue a spirit of best-of-the-best and sustaining improvement.

p.png)

%205000-10000Np.png)

Tiếng Việt

Tiếng Việt English

English