Over view

Ultra-low temperature test chambers are widely used in aerospace, semiconductor, biomedicine, materials science and other fields.It is a kind of test chamber used to test and determine the operation and performance of electrical, electronic, automotive electrical appliances, materials and other prod

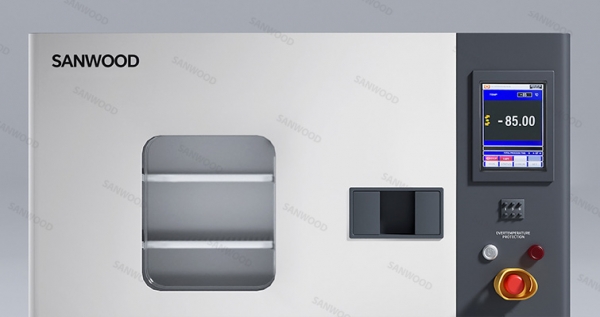

Advantages of Sanwood’s Test Chambers

The ultra-low Temperature Test Chamber can generate and maintain an environment as low as -70°C, -80°C, or even -196°C (close to liquid nitrogen temperature).

- The lowest temperature can reach -85℃, suitable for most product tests.

- Multi-layer hollow tempered glass observation window with automatic defogging function.

- Seamless welded SUS#304 high and low temperature resistant steel plate inner cavity.

- Each side is equipped with test lead space, convenient for charging and discharging cabinet placement.

The ultra-low temperature test chamber is a kind of test chamber used to test and determine the operation and performance of electrical, electronic, automotive electrical appliances, materials and other products in extremely low temperature environments.

Application fields of Low-temperature Test Chamber

Ultra-low temperature test chamber is a high-tech equipment, which is mainly used to simulate the storage and use conditions in extreme low temperature environment,Its application fields are very wide, the following are the main common application fields:

- Medical field: widely used in the storage and testing of drugs and biological products (such as vaccines, cells, tissues, blood, fertilized eggs, etc.), which need to be stored at low temperatures to maintain their biological activity for long-term preservation, research and use.

- Electronics industry: used to test the performance and reliability of electronic components at extremely low temperatures, which helps to find potential defects and problems and improve product quality.

- Aerospace: Test the environmental adaptability and reliability of aircraft equipment such as aircraft, missiles, and satellites to ensure their normal operation in extremely cold weather and high altitude environments.

- Food industry: used for the research and development of food preservation technology, by simulating ultra-low temperature storage conditions to extend the shelf life of food.

As a high-tech equipment, ultra-low temperature test chambers play an important role in many other industries, such as automobiles, electrical appliances, electronic communications, etc.

The Test Standards Of Low-temperature test Chamber

The test standards for ultra-low temperature test chambers are mainly determined by their application fields and industry requirements. The requirements for ultra-low temperature test chambers in different fields may be different, and the test standards may also be different. Of course, many international and industry ultra-low temperature test chamber test standards are clear. The following are some common test standards and specifications:

- IEC 60068-2-1: Environmental Testing Part 2: Test A: Low Temperature Tests. This is a standard for testing electrical and electronic equipment in low temperature environments.

- ASTM D3418: Used to determine the physical properties of polymers and other materials at different temperatures, which may involve testing in the ultra-low temperature range.

- ISO 16750: Automotive industry standard, involving testing of automotive electronic equipment under different environmental conditions, including low temperature testing.

Ultra-low temperature test chamber product testing standards involve multiple aspects to ensure that the performance and quality of the product meet specific requirements. It can effectively test and verify the performance and reliability of different materials and equipment under extreme low temperature conditions.

Control System Of Low-temperature Test Chambers

The controller system of Sanwood test chamber adopts world leading hardware and software systems to ensure that the test box operates under preset conditions, providing accurate and reliable experimental data to help users achieve precise control and data collection of various experimental conditions.

- Controller: The TEMI 1500 controller imported from Sanwontech in South Korea and the self-developed Siemens control system are used, equipped with RS232, RS485, and Ethernet communication ports.

- Programmable control: supports setting experimental programs, such as heating, cooling, holding time, etc., and executing multiple program settings.Support advance reservation for power on function.

- Multiple languages optional: English, Korean, Russian, Chinese, and Japanese.

- Precise control: able to accurately set and maintain specific temperature ranges and humidity levels, accurately simulate various environments.

- Remote monitoring: Using SAMWON-EZNET network remote technology to achieve remote control, the test chamber can be monitored at any time and emails can be sent to users' PCs and phones, enhancing convenience.

The specific control system of the test chamber may vary depending on the model, so it is necessary to carefully read the Sanwood Environmental Test Chamber Manual and follow safety operating procedures before use.

Refrigeration System Of Low-temperature Test Chamber

The refrigeration system of the test chamber is a complex and important system, and the quality of the refrigeration system is crucial for the accuracy and reliability of the test results.

- Sanwood has developed hot air refrigerant defrosting technology, which effectively melts the frost on the evaporator by injecting high-temperature and high-pressure refrigerant vapor into the heat exchanger inside the test chamber. This not only ensures that the evaporator does not frost, but also greatly reduces the energy consumption of the equipment.

- The refrigeration unit adopts international famous brands and cooperates with Japan's Eginomiya and the US Sporan to develop EPV series and XUP series quick opening solenoid valves for energy-saving systems, with an all-weather service life of over 15 years. And began to develop the new Danfoss AKV series throttling electronic expansion valve system, which is more efficient and energy-saving.

- Optimizing the layout of the refrigeration system adopts VRF (refrigerant flow control) technology based on PID cold end output principle to achieve low-temperature energy-saving operation, which can reduce energy consumption by 30% under low-temperature conditions.

- The refrigeration system adopts modular design, achieving low failure rate,less welding joints, high refrigeration efficiency, good reliability, simple maintenance, and low repair costs.

Technical data sheet

|

Model |

SM-712-CC |

SM-812-CC |

|

Internal Size(RCS) mm |

400*400*400 |

400*400*400 |

|

Outer Size(RCS) mm |

950*1200*630 |

950*1200*630 |

|

Volume (Lít) |

64 |

64 |

|

Weight (kg) |

145 |

145 |

|

Power Supply |

220V AC 50/60Hz 16A |

220V AC 50/60Hz 35A |

|

Temperature |

||

|

Temperature Control range |

-75°C ~ 180°C |

-85°C ~ 180°C |

|

Temperature fluctuataion |

±0.5°C |

±0.5°C |

|

Colling rate |

180.0°C ~ -75.0°C Wthin 100 mins, 1.7°C/min |

180.0°C ~ -85.0°C Wthin 95 mins, 2.2°C/min |

|

Heating rate |

-75.0°C ~ 180.0°C Wthin 85 mins, 3.0°C/min |

-85.0°C ~ 180.0°C Wthin 53 mins, 5.0°C/min |

|

Temperature unifomity |

±1.5°C (-40.0°C ~ 100.0°C) ±2.0°C (100.1°C ~ 180.0°C and -40.0°C ~ -85.0°C) |

|

Sanwood Environmental Testing Chamber Co.,Ltd established at 1995 with Taiwan technologies, with abundant capital invested at 2013 to become a backup listed company, we re-registered our company to be Guangdong Sanwood Technology Co.,Ltd. With more than two decades hard working in this industry, we built our own manufacture facility at 2017, capacity reaches to 12,000 square meters which allow us to provide customers with one-stop station products and services from R & D, Sheet metal processing, mass production, sales service, after-sales service, rent & lease, internal testing to import & export.

We dedicate to provide technologies and whole solutions with most secure and reliable environmental test chambers for our client.Achieved ‘National High-tech Enterprise’ award and became an CASC permanent member. Certified by ZRX with ISO9001:2015 and ISO14001:2015 and recently verified by Alibaba with Gold Plus supplier.

Our valued clients included but not limited to: Science & Research, Military Industry, National Defense, Universities & Colleges, Quality Inspection, Automotive, New Energy, Batteries, opto-electronic, AI, Precision electronics, electrical tools,medical,telecommunications. With clients points of view and demands-orientation, we consider every details in our product research & development and after-sales service to pursue a spirit of best-of-the-best and sustaining improvement.

.jpg)

Tiếng Việt

Tiếng Việt English

English